CINE researcher leads development of scalable photoelectrolyzer

A scientific article recently published in the prestigious journal ACS Energy Letters presents a system capable of producing hydrogen without generating carbon emissions, using only sunlight and water (free and abundant resources) and materials widely available in Brazil. A prototype of the equipment, a photoelectrolyzer, was successfully produced and tested by the authors of the work, both in the laboratory and outdoors.

Photoelectrolyzers are not yet on the market, but they represent an interesting possibility for the production of green hydrogen. Unlike conventional electrolyzers, these devices are energy self-sufficient; they do not need to be connected to a power source to function because they have an important component, the photoanode.

The photoanode is one of the two electrodes of a photoelectrolyzer. It is capable of absorbing sunlight and directly using its energy to promote a series of electrochemical reactions that ultimately result in the release of hydrogen from the water molecule. However, the large-scale production of efficient and stable photoanodes using abundant and low-cost materials has challenged the scientific community for several decades.

“In this work, we present an essential advance in this path, overcoming one of the main bottlenecks in the area: obtaining an efficient, stable, and scalable hematite photoanode,” says Flavio Leandro de Souza, professor at UFABC, researcher at LNNano – CNPEM, and member of CINE, who led the research.

Hematite is an iron oxide abundant in nature, considered very promising for photoelectrolysis, mainly because it does not degrade in contact with water. In the new work, the authors managed to increase the efficiency of the material without decreasing its stability, through the addition of small amounts of aluminum and zirconium oxides, which are materials available in Brazil.

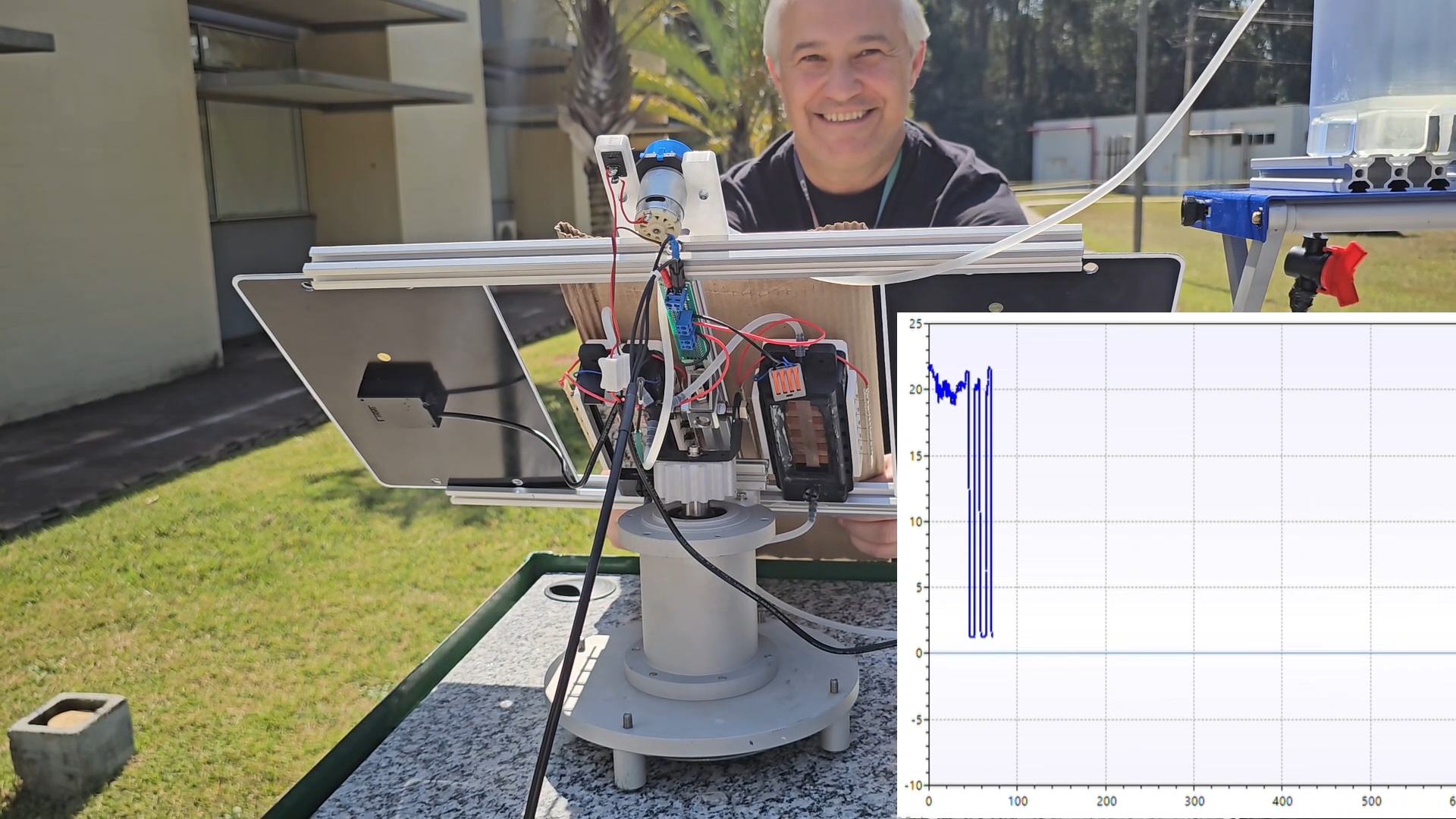

Concerned with the scalability of the processes, the researchers developed a method for producing photoanodes that can be scaled up to industrial levels. With it, the team produced 100 photoanodes, all with the same properties. Using these electrodes, the authors assembled a modular system: 10 photoanodes form a photoelectrolyzer, and ten of these devices operating together can form a one-square-meter module.

In laboratory tests using a solar light simulator, the system functioned stably for 120 hours. Furthermore, a prototype consisting of two photoelectrolyzers was tested outdoors and maintained the same efficiency verified in the laboratory, in addition to demonstrating robustness.

All the development and test work was carried out at CNPEM by a group of six researchers. The team collaborated with Professor Renato Gonçalves, from IFSC-USP, to build the large-area solar light simulator used in the laboratory tests.

Currently, the authors are working on the development of the other electrode of the photoelectrolyzer, the cathode, to use only sunlight as an energy source. “The next step, already underway, is a module operating 100% on solar irradiation, with each photoreactor composed of a photoanode and a photocathode,” announces Professor Flavio.

According to the scientist, the system would be ideal for use in industries that need green hydrogen at specific points, directly injecting the gas into industrial processes. Being modular, the technology would allow for easy adaptation of the size and capacity of the photoelectrolyzer to the industry’s needs.

Further scaling up the production of the equipment is within the authors’ plans, but this would require significant investments in infrastructure and safety to carry out the necessary tests. “It’s a crucial step, and collaboration with interested companies is essential,” says Professor Flavio.

This research was funded by FAPESP, Shell, CNPq, and Capes, in addition to strategic support from ANP.

Paper reference: Rodríguez-Gutiérrez, L. R. P. Peregrino, G. H. Morais, F. Coa, D. S. T. Martinez, R. V. Gonçalves, F. L. Souza. Photoelectrode Fabrication and Modular PEC Reactor Integration for Stable Solar Hydrogen Production. ACS Energy Lett. 2025, 10, 10, 4769–4776. https://pubs.acs.org/doi/10.1021/acsenergylett.5c02340

CINE members who participated in the work: Flavio L. de Souza.

Contact

Flavio Leandro de Souza

UFABC e CNPEM