Material developed at CINE optimizes emerging hydrogen production technology.

A material produced with abundant elements using a technique widely employed in industry makes the anion exchange membrane electrolyzer more efficient – a promising piece of equipment for the production of low-carbon hydrogen.

“The advances achieved in this work help to make the technology more reliable, efficient, and economically attractive for future applications,” says Professor Lucia Helena Mascaro (UFSCar), who led the research. Lucia is the vice-coordinator of the Low-Carbon Hydrogen Program at CINE and director of Research at CDMF.

Electrolyzers are devices that use electricity to split the water molecule, generating hydrogen. When the electricity comes from renewable sources, the hydrogen generated is considered “green.”

In particular, anion exchange membrane electrolyzers are easily integrated with renewable electricity sources, in addition to exhibiting the robustness of other types of electrolyzers already established in the market. On the other hand, these devices have low efficiency in the electrodes, which are the components responsible for splitting the water.

Seeking to overcome this limitation, researchers from UFSCar and EMBRAPA collaborated with scientists from German institutions to develop electrodes that are more efficient than conventional electrodes, which are based on ionomers (materials from the polymer group).

“The research combined the expertise of the German group in the development and operation of electrolyzers with our know-how in the synthesis of catalysts, especially through the electrodeposition technique,” says Professor Lucia.

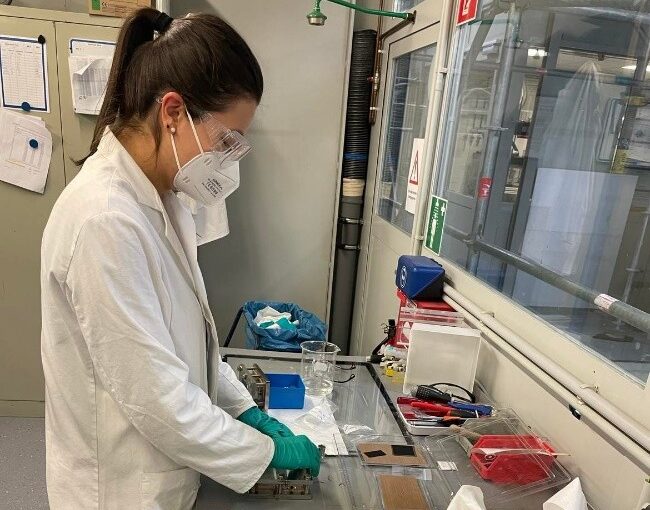

The scientific team used elements abundant on the planet (nickel, iron, and sulfur) to develop a nanostructured thin film that combines durability, large surface area, excellent electrical conductivity, and low resistance to charge transfer.

The film was deposited on one of the equipment’s electrodes (the anode), composed of nickel fibers. Finally, the authors carried out laboratory-scale tests under controlled conditions, completing a step that is fundamental for subsequent large-scale application. One of the main results of the work was to reduce the voltage required to perform water electrolysis in the equipment.

“This functional coating transformed the metallic surface into a highly efficient system for hydrogen production, ensuring good electrical conductivity and stability during operation,” explains Professor Lucia.

The main innovation of this research was the strategic use of electrodeposition techniques in the synthesis and deposition of the material. In fact, this method, widely used in industry, allowed for precise control of the material’s morphology and microstructure. The result was a uniform, crack-free, and highly adherent film.

The new approach allows for the development of more efficient and durable anion exchange membrane electrolyzers, offering a promising path for future applications in the sustainable production of hydrogen.

The research was funded by FAPESP, Shell, CNPq, and Finep, in addition to strategic support from ANP.

Reference of the scientific article: Marina Medina, Anelisse Brunca da Silva, Lu Xia, Wulyu Jiang, Andreas Glüsen, Caue Ribeiro, Lucia Helena Mascaro. Tailoring NiFeS microstructure through electrodeposition for high-performance anion exchange membrane water electrolysis. Journal of Power Sources. Volume 657, 30 November 2025, 238128. https://doi.org/10.1016/j.jpowsour.2025.238128.

CINE members who participated in the work: Anelisse Brunca da Silva, Caue Ribeiro, and Lucia Helena Mascaro.

Contact

Lucia Mascaro

UFSCar