CINE article provides guidance for optimizing next-generation fuel cells

A scientific article recently published by CINE researchers and collaborators brings together essential information to improve the latest generation of fuel cells, known by the acronym SOFCs (solid oxide fuel cells).

SOFCs are devices capable of generating clean, renewable energy with high efficiency. To produce electricity, they require fuel, but unlike other fuel cells, SOFCs operate with a variety of substances, such as bioethanol, methane, or hydrogen. Therefore, they can be useful in a wide range of contexts, from electric vehicles to communities far from the power grid.

However, this technology still has limitations regarding the durability and stability of the devices, mainly due to their high operating temperatures, which can reach 1,000 °C. Aiming to overcome these challenges, metal-supported SOFCs (MS-SOFCs) emerged near the beginning of this century.

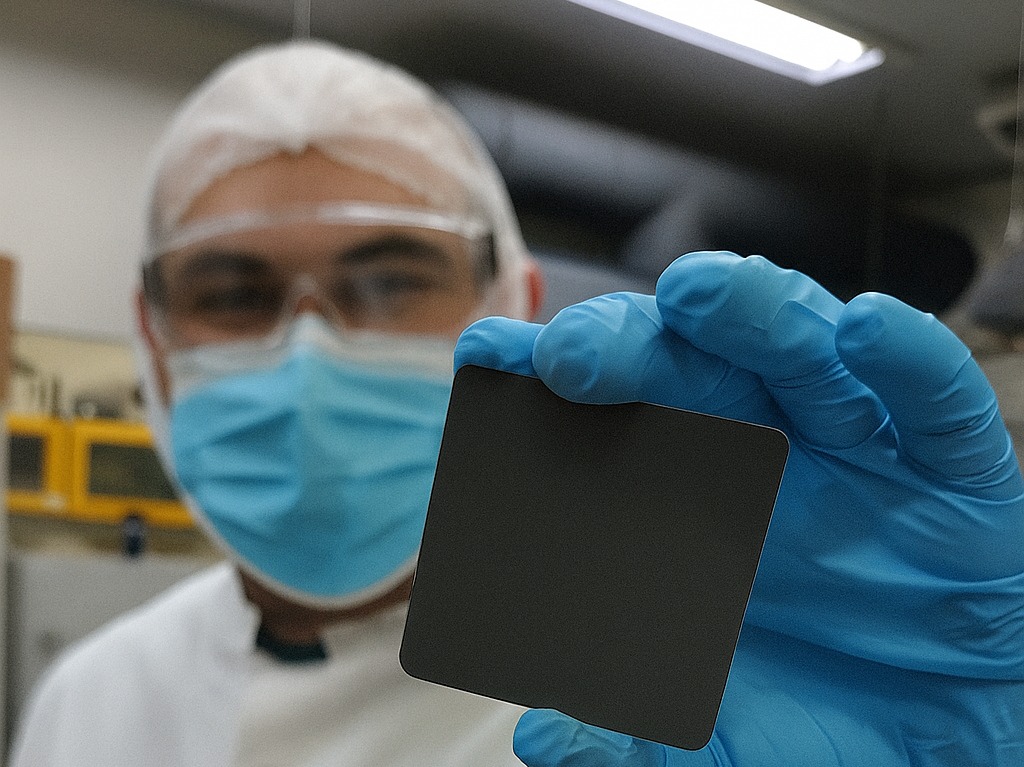

“Let’s imagine a fuel cell as a sandwich of materials,” suggests Professor Gustavo Doubek (Unicamp). “In this sandwich, the metal support acts as the firm base that supports the entire structure. It’s important because it provides strength so the cell doesn’t break easily, helps conduct electricity efficiently, and facilitates the entry and exit of gases, as it’s made of porous metal, full of “paths” for the fuel to circulate,” explains the researcher. “This means the cells are more durable, function more stably, and can operate for much longer without failures,” he adds.

Doubek is one of the lead authors of the article, which specifically addresses advances in the development of the metal support. According to the scientist, supports made of stainless steel-based metal alloys have shown good results in practice, as they combine robustness with corrosion resistance.

At CINE, Doubek conducts research focused on the development of MS-SOFCs. Currently, these efforts include: production of 100% Brazilian prototypes, testing of porous metal alloys to understand which ones best withstand operating conditions, and performance studies to increase the cells’ power and durability.

“The results already show that Brazil has the capacity to develop its own technology in this area, reducing dependence on foreign suppliers and opening up opportunities for applications in clean energy and sustainable mobility,” says Doubek.

In the scientific article, researchers and engineers can find valuable guidance for further improving metal supports for SOFCs. The text discusses advances in the manufacturing, materials, and surface treatments of these components, with a focus on finding scalable and cost-effective techniques.

The study reported in the article involved researchers from Unicamp and a scientist from King Abdullah University of Science and Technology (Saudi Arabia) and received funding from FAPESP, FUNDEP, and CNPq.

Paper reference: João P. J. de Oliveira, Fabio C. Antunes, Thiago Dias, Reinaldo Cesar, Guilherme G. Silva, Julian Hunt, Gustavo Doubek, Hudson Zanin, Porous metal substrates for solid oxide fuel cells: Manufacturing techniques and future perspectives, Ceramics International, Volume 51, Issue 9, 2025, Pages 10951–10972. https://doi.org/10.1016/j.ceramint.2025.01.059.

CINE members who participated in the work: João Pedro Jenson de Oliveira (doctoral student), Fábio Antunes, Thiago Dias, and Reinaldo Cesar (postdoctoral fellows), Gustavo Doubek (Co-Principal Investigator of the Advanced Energy Storage division), and Hudson Zanin (Principal Investigator of the Advanced Energy Storage division).

Contact

Gustavo Doubek

UNICAMP